MONALITE® M1T

MONALITE M1Tis a high-density calcium silicate with a density of 850 kg/m3.

Specially developed for contact with light non-ferrous metals, it does not pollute aluminum and its alloys, resists well to thermal shocks, is not wetted by liquid metals, remains dimensionally stable up to 1000° C.

It is also compatible with foundry poteyages containing graphite and boron nitride.

MONALITE M1T does not develop corundum.

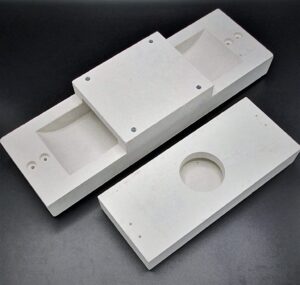

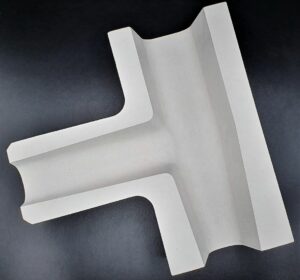

Easily machinable, this calcium silicate is particularly suitable for the production of machined parts such as dams, floats, nozzles, feeder sleeves, spouts, pointers, etc. for continuous casting and non-ferrous metal die-casting systems.

MONALITE M1T's thermal and mechanical properties also make it suitable for glass processing, various heat treatment applications and thermal bridge break applications ( SANPON flanges).

Thermal conductivity:

0.274 W/mK at 200° C

0.283 W/mK at 500° C

0.294 W/mK at 800° C

Linear shrinkage :

<0.5 % après 12 h à 750° C

Resistances:

Cold compression ≤ 20 Mpa

Bending > 6 Mpa

Available formats:

Plates of 2500 x 1200 mm

Thicknesses:

13.1 / 25.8 / 38.5 / 51.2 / 76.6 / 102 mm